Electric motors - spring-applied brakes

Discover our high-quality spring-applied brakes for reliable and safe braking. As experts in drive technology, we offer a wide range of spring-applied brakes for different applications and requirements.

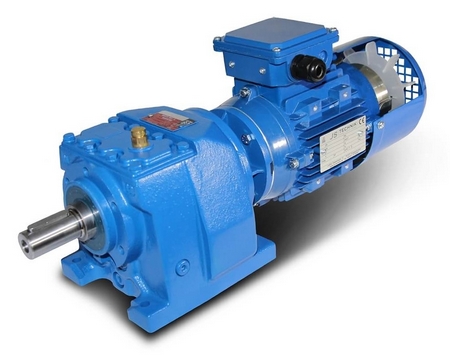

Helical geared motor with brake

How the electric motor brake works

Spring-applied brakes are predominantly used here; they work according to the closed-circuit principle. This means that the braking effect is generated in the de-energized state using an integrated spring package. The electrically generated magnetic field attracts the armature disk against the spring force via an air gap and releases the axis of the drive to rotate.

Double spring-loaded brakes

Double brakes are used where high safety requirements are required. These two spring-applied brakes, which act independently of each other, are ideal for use in elevators and stage technology due to their special noise reduction.

DC braking

The K series electromechanical spring brake is a DC brake. The purpose of the brake is to stop the rotation of a mechanical shaft.

The main features of the K series brake are:

• Extremely robust structure

• Extremely quiet intervention and operation (< 70 dBA according to Directive 98/37/EEC)

• Cost-effectiveness thanks to the easy assembly of the brake group

• Good heat dissipation. This is done via the fan and/or the motor cover, which must necessarily be made of cast iron or steel as it also serves as a braking surface

• The electromagnet coil is fully bonded with epoxy resin and the mechanical parts are protected by galvanic treatment with zinc plating

AC braking

The AC series electromechanical spring brake is an AC brake. The purpose of the brake is to stop the rotation of a mechanical shaft. The correct function of the brake can only be guaranteed by following the instructions on the “Dimension calculations” page.

The main features of AC series brake are:

• Extremely robust construction

• Easy assembly of the brake unit

• Quiet operation (< 70 dBA according to Directive 98/37/EEC)

• Good heat dissipation thanks to the die-cast aluminum structure and the electric motor fan

• The electromagnet coil is completely glued with epoxy resin

Function of the electric motor brake

Spring-applied brakes are predominantly used here; they work according to the closed-circuit principle. This means that the braking effect is generated in the de-energized state using an integrated spring package. The electrically generated magnetic field attracts the armature disk against the spring force via an air gap and releases the axis of the drive to rotate.

SEO= Spring-applied brakes for electric motors. Electric motors - spring-applied brakes