-

Products

- Electric motors

-

Geared motors

-

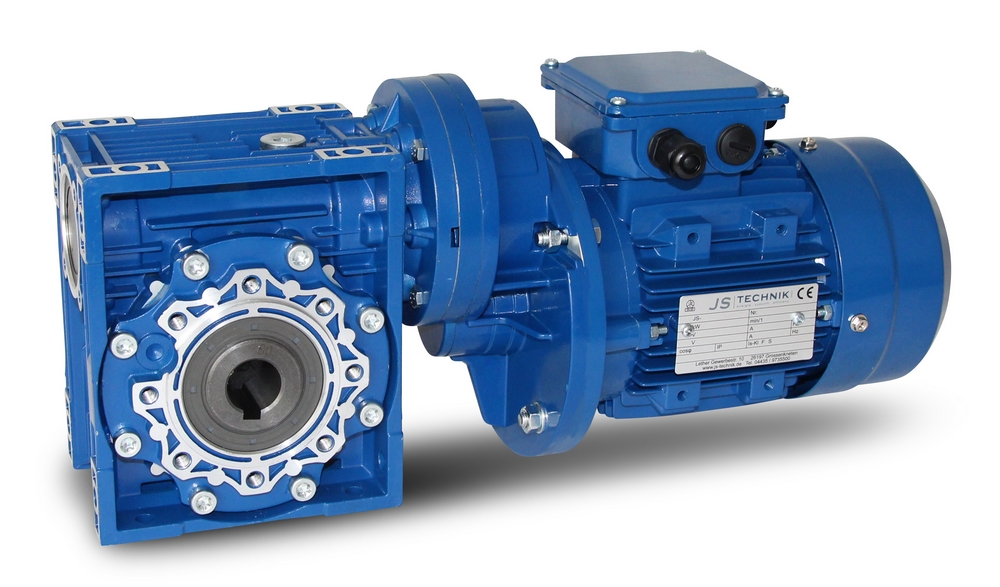

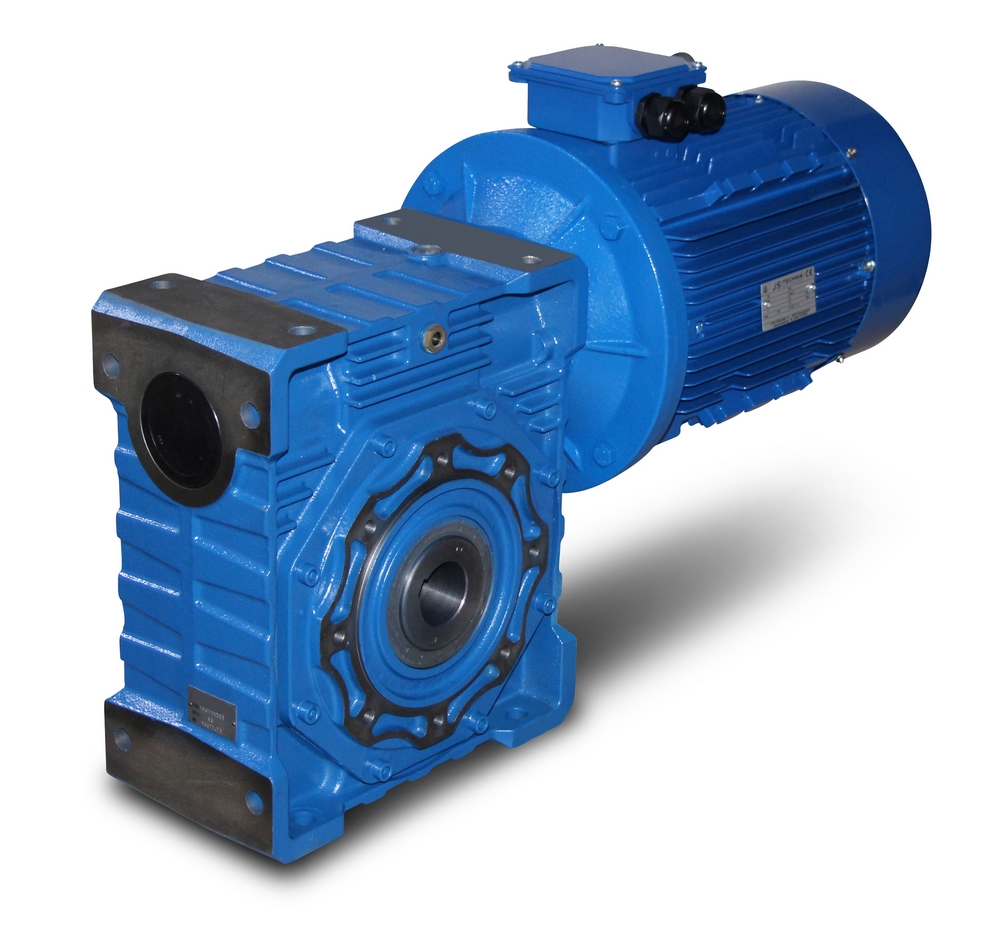

Worm gearbox with motor

- Worm gearbox without motor

- Helical geared motors M-Series

- Helical bevel gear motors K-Series

- Parallel shaft geared motors D-Series

- Planetary geared motors P-Series

- Heavy duty gears - H series

- Direct current - Worm gear motors

- Direct current - Helical geared motors

- Direct current - Helical bevel gear motors

- Direct current - Parallel shaft geared motors

- Stainless steel - Worm gear motors

- Stainless steel - Helical gear motors

- Stainless steel - Bevel gear motors

-

Worm gearbox with motor

- Frequency inverter

- Geared motors with speed control

- Accessories electric motors

- Accessories geared motors

- Accessories frequency inverter

- Special and remaining items

- Contact

- Imprint

- FAQ

- Online Calculator

- Download

Worm gear reducer motors available at short notice

JS-Technik GmbH is specialized on a wide range of challenges in the professional drive technology field with a focus on electric motors, frequency inverters and geared motors.

Geared motor size and motor power

In our drive technology online shop, you find a selection of worm gear motors with very different speeds expressed in rpm (i.e. rev/min or min-1) and in construction sizes NMRV, 30, 40, 50, 63, 75, 80, 100, 125 with a power of 0.12 kW, 0.25 kW, 0.37 kW, 0.55 kW, 0.75 kW, 1.1 kW, 1.5 kW, 2.2 kW, 3.0 kW, 4 kW, 5.5 kW as well as 7.5 kW.

Worm gear with motor and external fan

Shaft diameters and torques

Aluminum worm gearboxes are available with the following hollow shafts: 14 mm, 18 mm, 20 mm, 25 mm, 28 mm, 30 mm, 35 mm, 40 mm and 45 mm. The output torque depends amongst other things on the motor power, the efficiency and the output speed. While considering these parameters, we supply worm gearboxes in a torque range of 10 – 2000 Nm. The torque is determined from the following equation, where M is the torque in Nm, P is the motor power in kW and n is the speed in min-1: M = 9550 · P / n.

Worm gear motor/grill gear motor

Worm gearbox function

Worm gearboxes, also known as worm gear speed reducers, consist of a shaft fitted with one or several pitches, i.e. the worm, and a helical geared pinion, i.e. worm gear, meshing with the worm. The two shafts form an angle of 90°. This type of gearbox is specifically used for applications requiring high gear reductions in one step. There are worm gear motors with left-hand and right-hand pitches. These motors can operate in both senses of rotation. Full flexibility of installation includes foot, flange and centering solutions with a torque support. If the efficiency drops below 50%, self-locking occurs.

Worm gear motor in gray cast iron design

Worm gearbox installation

The motor terminal box can be mounted in steps of 90° on the motor, as required. The JS geared motor can be mounted in almost any position required. These positions are designated M1, M2, M3, M4, M5, M6.

Worm gearboxes with their advantages

Based on a high degree of interchangeability and the quietness of running of geared motor components (IEC flange), the customer will benefit from greater flexibility of construction options available, reduced costs, shorter delivery times and simpler installation & maintenance.

Worm gearbox combinations

Worm gearboxes are available in various speeds, i.e. from 2 to 600 rev/min (revolutions per minute). In many cases, motor / worm gearbox combinations are needed to be designed to match customer’s individual requirements. With decades of experience and our own final assembly, we are a perfect partner for businesses that need external expertise in a large spectrum of issues – whether it is a worm gearbox with brake motor, a special shaft, a grill rotisserie motor with gearbox, a worm gear motor with a specific supply voltage (500V) or explosion protected design.

SEO= Worm gear motor - short delivery time - from stock. Worm gear reducer motors available at short notice