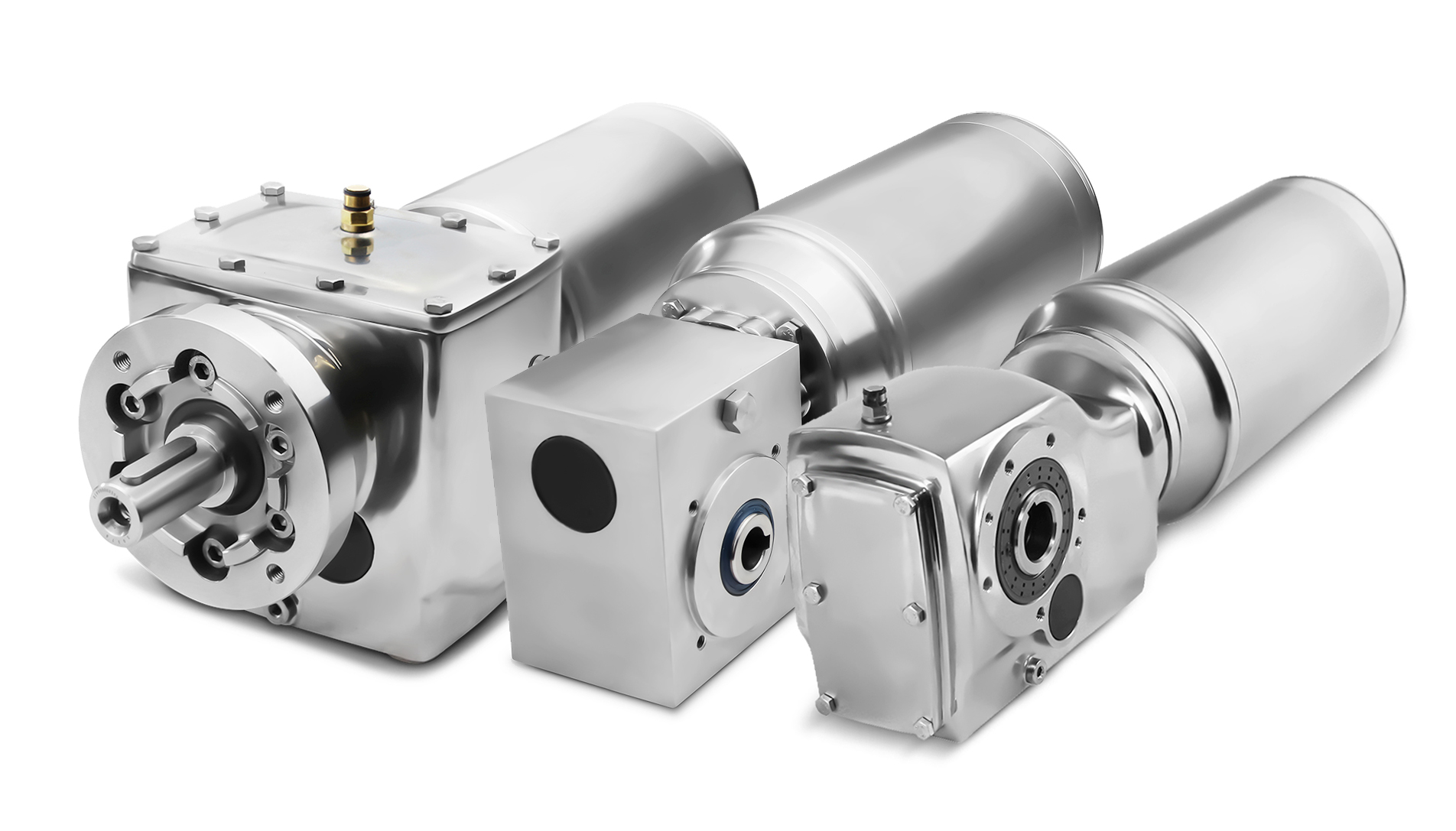

Stainless steel geared motors and accessories

The stainless steel geared motors and accessories are manufactured in accordance with HACCP and EHEDG regulations. They are extremely corrosion resistant and offer exceptional resistance to harsh chemicals.

Advantages of stainless steel geared motors

The stainless steel worm gear motors are manufactured in accordance with HACCP and EHEDG regulations. They have the advantage of extreme corrosion resistance and offer exceptional resistance to harsh chemicals. With conventional gears, when cleaning, the paint or metal chipping off due to aggressive cleaning agents can lead to significant production problems. To avoid this, geared motors made of stainless steel are used. The geared motors are available with matching flanges, output shafts, in terminal box design.

Stainless Steel Gearmotors

Technical features:

- Smooth surface (food, beverage, pharmaceutical industry , etc.)

- No dirt deposits and bacterial foci

- Reduced projecting edges due to missing cooling fins

- Good cleaning properties

- Up to 1.5kW in protection class IP69K, greater power in IP66

- Three-phase motor without fan (important clean room property)

- Constructed for rough continuous operation

- Above-average durability

- Optimum running smoothness

Protection class IP69K

The IP69K protection class was developed for high-pressure jet cleaning at high temperatures. The number "6" stands for protection against the ingress of dust, the number "9" for protection against high-pressure cleaning at close range. The degree of protection IP69K was introduced in 1993 and is based on the DIN40050-9 standard. It was originally developed for motor vehicles to protect against the ingress of foreign bodies such as dust or dirt and hot water jets. The latest version of the IEC60529 standard only speaks of IP69 (IP69K = IP69).